One of the cool things about vacuum based milkers is that they can suck in their own lube and if set up correctly never run dry. So in theory one could leave a sub on the milker for days 😈 (Well, please don’t in reality, there may be other things causing issues).

Lube

As I had mentioned in part 2 already, there’s a third hose for the lube supply going to the receiver. I’m using a transparent 3mm hose.

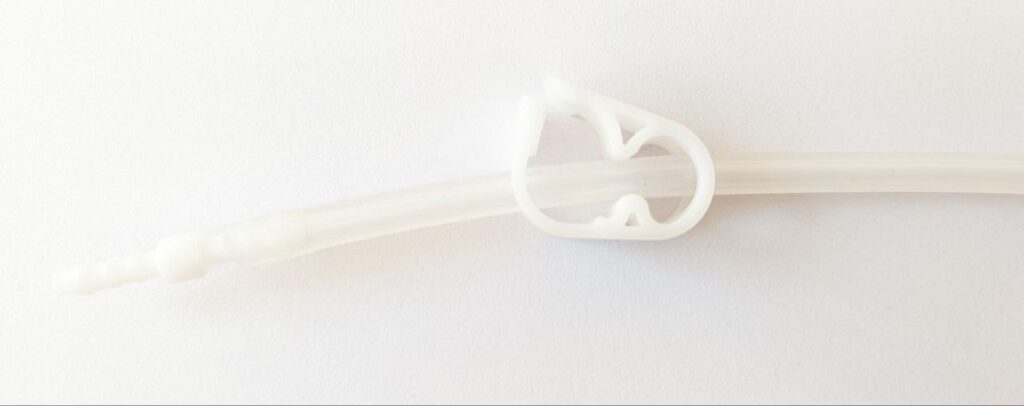

On the receiver-side I added a clamp to shut off and regulate the flow of lube and a simple hose connector. I’m planning to upgrade to a PMC connector though.

On the receiver-side I added a clamp to shut off and regulate the flow of lube and a simple hose connector. I’m planning to upgrade to a PMC connector though.

On the “machine”-side, I’m using a cheap PE bottle and a custom printed cap. The vacuum in the receiver sucks in the lube from the bottle. You need to restrict the lube flow carefully using the clamp. Otherwise you will run out of lube in just a minute.

Before playing I prepare a mix of roughly a quarter table spoon J-Lube powder and 500ml water in the bottle. Use a mixture to your own liking or any other kind of lube, but make sure it is fluid enough to be sucked in through the hose. If I want to be fancy, I add a drop of food coloring, so it’s easier to see how much lube is left and how much has already collected in the coffee can.

This concludes the description of the basic milker. More extensions will follow though.

This is how it looks when in use 😈

BOM

- 1 Coffee can

- 1 Pressure regulator

- 1 Pulsator

- 1 Vacuum gauge

- 6 M8x1 Nuts

- 6 10mm ID O-Rings

- 6 hose fittings

- 1 3D-printed support for the pulsator

- 3m 8mm hose color 1 (constant suction)

- 3m 8mm hose color 2 (pulsating suction)

- 3m 3mm hose (lube supply)

- some 8mm hose color 3 (to pump)

- 3 PLC male hose coupling without valve

- 5 PLC female hose coupling with valve

- 1 PLC male hose coupling with valve

- 1 PLC male hose coupling 90° with valve

- 1 straight connector (for lube, alternatively use a male and a female PMC connector)

- 2 valves

- 1 vacuum pump

- 1 receiver

- 1 bottle

- 1 3D-printed cap