Since we covered the heart of the milking machine in part 1, it’s time for some of the other parts.

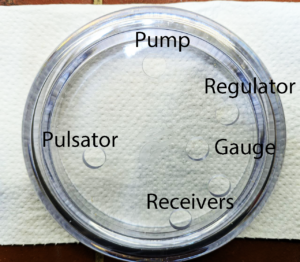

The receiver

Of course something needs to “do the work” 😈. I went for a standard “SPT” receiver from SeriousKit. Their build quality is fantastic and absolutely worth the money. They keep adding new options and I’d love to eventually try out more.

Of course something needs to “do the work” 😈. I went for a standard “SPT” receiver from SeriousKit. Their build quality is fantastic and absolutely worth the money. They keep adding new options and I’d love to eventually try out more.

I would highly recommend just going for their receivers. They just work, I never had any issues and their customer service is great and friendly. I was thinking of building a receiver myself, but I’m lacking the tools. So considering everything buying a reasonably priced SPT was the best decision for me.

When selecting which one to get, make sure you get the right diameter. You want neither too large because it will lead to air streaming around the penis which leads to very weird sensations. You also don’t want it too narrow, because things simply won’t fit or be too uncomfortable.

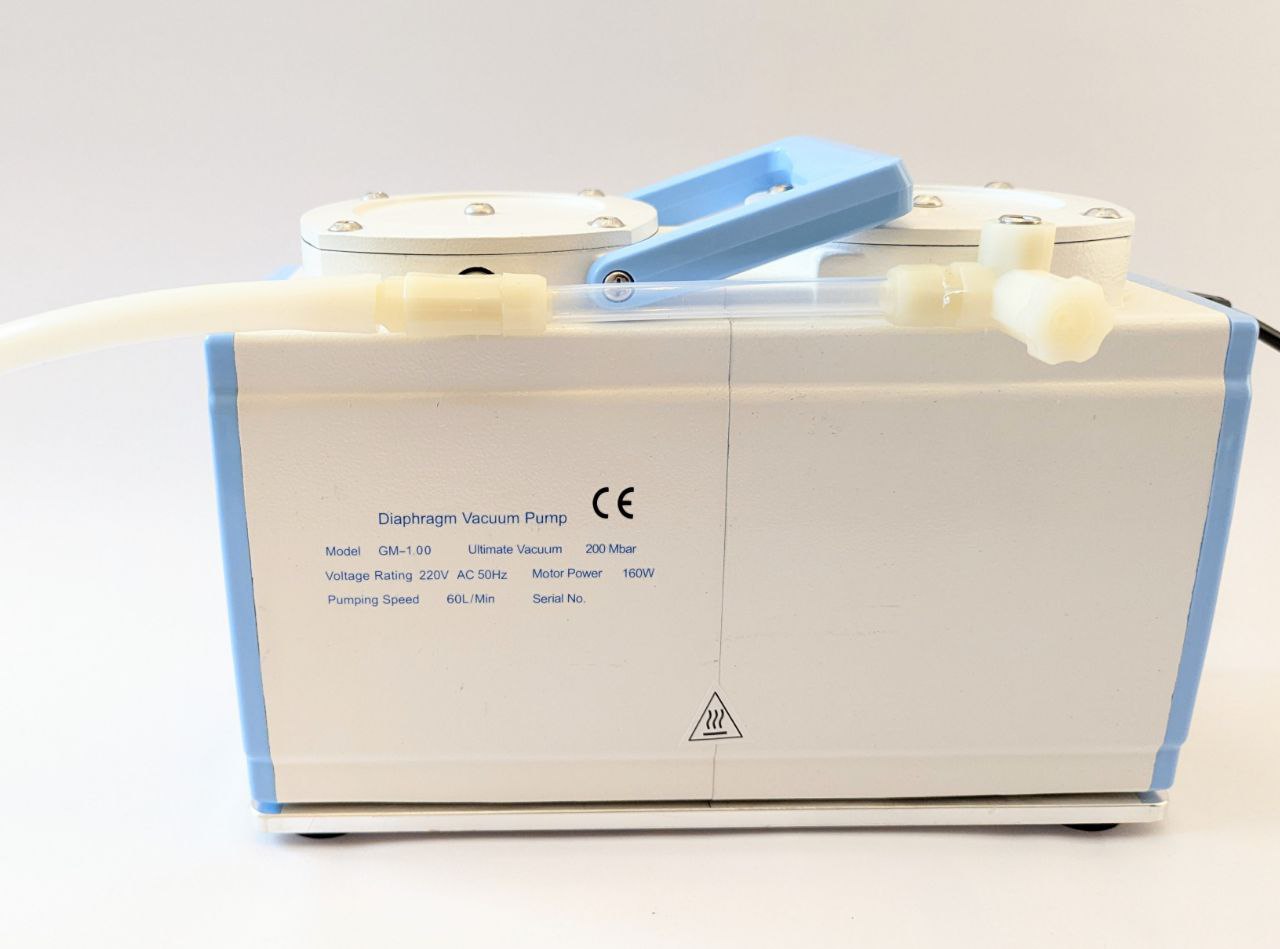

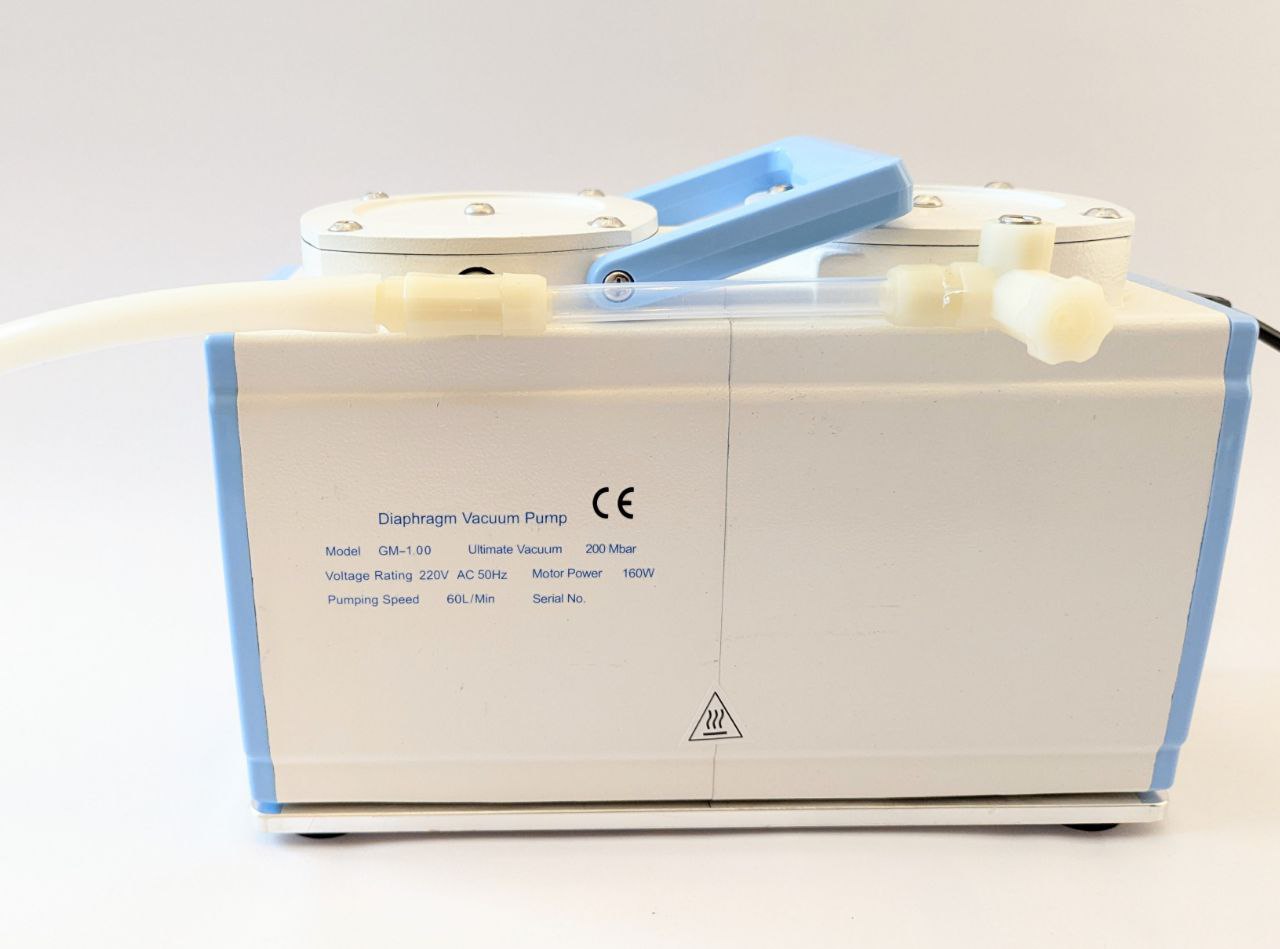

The pump

You will need a vacuum pump that has a throughput of at least 60 l/min. I went for the one from SeriousKit as well, which is a Chinese GM-1.00. The benefit is that it’s oil free and therefore requires no maintenance. On the other hand there are cheaper options, especially when import taxes, handling fees and other 🏴☠️🌪☠️ costs after Brexit get added. You may even find ones that have a higher throughput on eBay, AliExpress or some other local source.

If you are into making your own silicone toys as well, you probably have a pump already anyway 😜

I added a short tube and a PLC female coupler without valve.

The pump is quite loud and certainly not something I want to have anywhere near when playing. So I put the pump behind as many closed doors as possible and run a 10m long “extension” hose to the play area. It has a PLC male connector and a PLC female connector on the ends. This connects the pump with the coffee can aka. milker.

To turn on and off the pump without having to run to wherever it is, I use a Shelly Plug S.

I got a recommendation from a friend for this pump. It actually seems much better suited for a milker as it has higher throughput and is much cheaper than the one I have. He successfully used it. I haven’t experienced it myself yet.

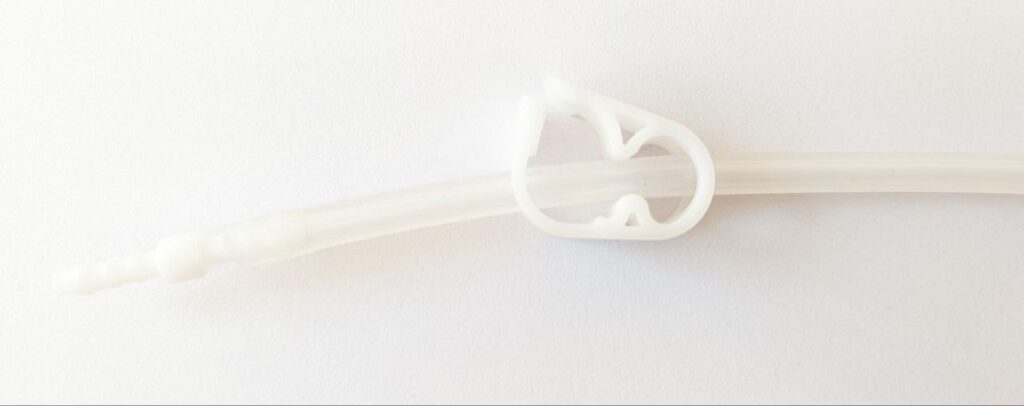

Hoses

You guessed it, there needs to be a connection from the milker to the receiver. We will need three tubes. One permanent suction, one pulsating suction and one for the lube supply. I color coded the tubes on the milker and the hoses. Black for permanent, red for pulsating. I did use transparent for “clean” to the pump and for the lube supply. In retrospect I should have chosen four different colors. But since the transparent lube and the transparent “clean” suction to the pump have different diameters, this is not too big of an issue. The color coding helps when you are playing with people who haven’t used the milker too often yet or are not very technical. Just tell them to follow the colors.

My hoses are around 2.5m long. You don’t want it too long to not have too much air volume in the hoses. But you also want them long enough to be able to easily position things. I would prefer a tad longer ones, maybe 3m, but 2.5m works most of the time.

You will need valves to gradually restrict air and lube flow. For the vacuum hoses I used cheap valves from amazon. For the lube these clamps.

I have a short acrylic tube in the black “permanent suction” hose to gauge how much lube and possibly other liquids 😈 are getting sucked out. I got the SeriousKit Venus conversion kit, and therefore had the tube. But I would argue that it’s not really necessary, so you should be fine without.

The black hose for the continuous suction has straight male PLC connectors on both ends. This will allow to easily flush it with water after use. For the red one for the pulsating suction I used ones with a built in valve. In normal operation they should never see any liquids and when cleaning the valve helps keeping them dry inside. I used an angled one on the receiver side and a straight one on the milker side.

All three hoses are tied together with cable ties, so you can run them neatly to wherever you need them.

In the next part I’m going to cover the lube supply and a complete BOM. Stay tuned.

On the receiver-side I added a clamp to shut off and regulate the flow of lube and a simple hose connector. I’m planning to upgrade to a PMC connector though.

On the receiver-side I added a clamp to shut off and regulate the flow of lube and a simple hose connector. I’m planning to upgrade to a PMC connector though.

Of course something needs to “do the work” 😈. I went for a standard “SPT” receiver from

Of course something needs to “do the work” 😈. I went for a standard “SPT” receiver from

It’s a very compact version of a standard milking machine as

It’s a very compact version of a standard milking machine as